Technology news

Technology

Pason DataLink: a faster, more streamlined drilling data solution

STORY: Published May 5, 2020

Although we’re currently in uncertain times, Pason has remained a reliable energy services and technology provider to our customers.

Drilling Data

KPI Reports: A daily look at critical statistics to help your business objectives

PDF: Published on Pason, April 24, 2020

Automated KPI Reports – Daily Reports

Pason’s Daily KPI Reports provide critical statistics and valuable insights into the previous day’s operations. These KPI reports are generated using sensor data, and can be retrieved from the DataHub, Pason Live mobile app, or auto-generated daily email.

Drilling intelligence

A DAS case study of drilling successful wells in the Bakken region

PDF: Published on Pason, April 24, 2020

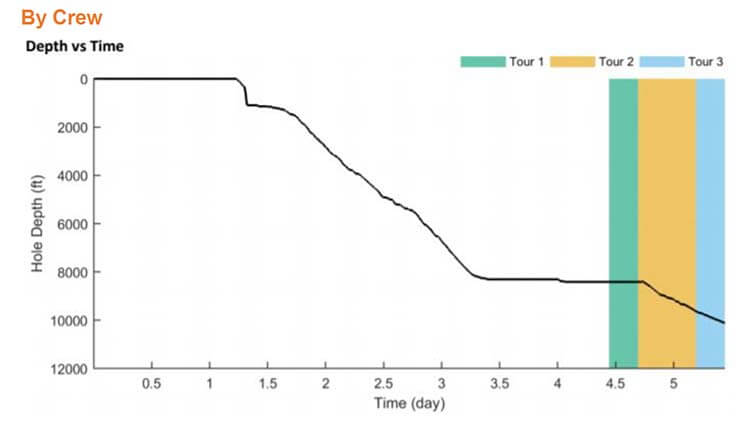

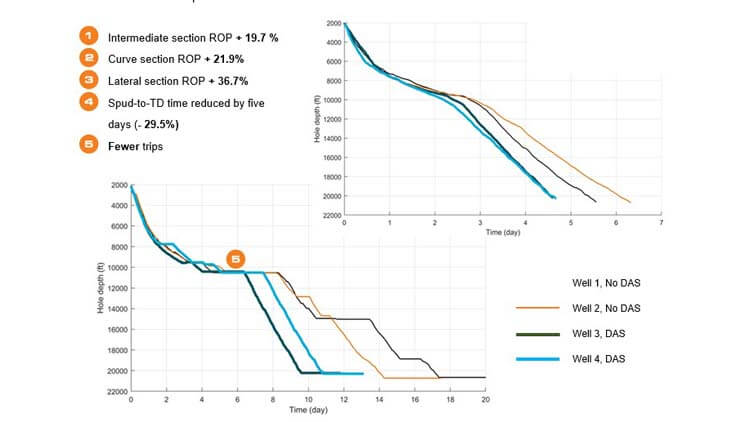

DAS – Case Study

In 2019, we closely studied a Bakken pad rig as it drilled four offset wells. The rig drilled the wells with and without DAS, which provided excellent comparative data. The crew drilled wells 1 to 4 in sequential order: wells 1 and 2 without DAS, wells 3 and 4 with DAS.

The results speak for themselves.

Drilling Data

Weight on Bit, Differential Pressure and the algorithm that improves the quality of your data

SPE PAPER: Published on One Petro, April 2, 2020

An Algorithm to Automatically Zero Weight on Bit and Differential Pressure and Resulting Improvements in Data Quality

Weight on bit (WOB) and differential pressure (DIFP) are two essential parameters derived from surface sensors during the drilling process. However, there can be significant errors in these measurements due to improper zeroing of these traces. Regular zeroing of WOB is important to ensure that it is calibrated for additional stands that have been added to the drillstring. Similarly, regular zeroing of DIFP is important to ensure that added hydrostatic pressure, which increases with depth, is taken into account, and to ensure that DIFP has been calibrated to the correct pump rate. In this paper, we quantify the errors due to forgotten and incorrect zeroing, and discuss an algorithm that was developed to automatically zero WOB and DIFP to eliminate these errors.

This study has two main sections. In the first section, the current practice of zeroing WOB (prior to rotary drilling) is analyzed in 40 onshore wells. It is found for 86% of all stands that WOB is either zeroed incorrectly or not at all. An algorithm is developed to determine the appropriate time to perform the zero WOB operation. Using this algorithm, it is found that the average WOB error per stand due to improper zeroing is 16.8 and 17.6% in the vertical and lateral wellbore sections, respectively. Further, it was found that repeated forgotten zeroes could result in large errors, particularly in the vertical where 8% of stands have WOB inaccuracies of more than 30%. In the second section, the analysis is repeated for DIFP and it is found that zeroing DIFP is forgotten in 51% of all stands, resulting in errors of 17.5 and 8.9% in the vertical and lateral, respectively. In the vertical, 9.9% of stands have DIFP inaccuracies of more than 30% due to forgotten zeroing. Applying these algorithms to historic data can eliminate these errors, and improve the effectiveness of data-based drilling optimization and analytics. Further, these algorithms could be implemented in an electronic drilling recorder (EDR) to improve the quality of real-time data at the rig.

Copyright © 2020 Society of Petroleum Engineers

Credits

Adam C. Neufeldt (Pason Systems)

Stephen W. Lai (Pason Systems)

Sean D. Kristjansson (Pason Systems)

Drilling intelligence

New patent issued to Pason for drilling data technology (USA)

PATENT: Published on United States Patent, March 17, 2020

Method, System, and Medium for Controlling Rate of Penetration of a Drill Bit

Methods, systems, and techniques for controlling the rate of penetration of a drill bit use drilling parameter measurements read from drilling parameter sensors to evaluate control loops, with the output of one of the control loops at any given time being used by an automatic driller to control the rate of penetration. For each of the drilling parameters, the automatic driller reads a drilling parameter measurement, determines an error measurement that represents a difference between a drilling parameter setpoint and the drilling parameter measurement, and from the error measurement determines an output signal proportional to the rate of penetration of the drill bit. The output signal of one of the control loops is subsequently selected and used to control the rate of penetration.

Credits

Holt; Trevor Leigh (Calgary, CA)

Wilson; Thomas William Charles (Calgary, CA)

Hepburn; Quinn Harrison (Calgary, CA)

Drilling intelligence

Presentation: See how closed-Loop drilling optimization reduces drilling costs through any formation

PRESENTATION: Published on Pason, March 3, 2020

Large-Scale Deployment of a Closed-Loop Drilling Optimization System: Implementation and Field Results

Presentation from the March 2020 Society of Petroleum Engineers (SPE) conference in Galveston, Texas.

Credits

Pason Systems: Stephen Lai, James Ng, Aaron Eddy, Sergey Khromov, Dan Paslawski, Ryan van Beurden, Lars Olesen

ExxonMobil Upstream Research Company: Gregory Payette, Benjamin Spivey

Drilling intelligence

New patent issued to Pason for drilling data technology (CA)

February 18, 2020

New patent issued to Pason for drilling data technology (CA)

PATENT: Published on Canadian Intellectual Property Office, February 18, 2020

Method and Apparatus for Drilling a New Well Using Historic Drilling Data

A method for drilling a new oil or gas well in a selected geographical location comprises extracting drilling modes from historic drilling data obtained from a group of drilled wells in the selected geographical location using a pattern recognition model. Each drilling mode represents a distinct pattern that quantifies at least two drilling variables at a specified drilling depth. The method also comprises selecting a sequence of drilling modes at positions along a reference well as reference drilling modes that represent more efficient values for a selection of one or more of the at least two drilling variables compared to other extracted drilling modes; associating drilling parameter settings with the reference drilling modes; and drilling the new oil or gas well applying at least some of the drilling parameter settings.

Credits

KRISTJANSSON, SEAN (Canada)

LAI, STEPHEN (Canada)

TREMAINE, DEAN (Canada)

Drilling intelligence

Avoid destructive vibrations with instant notifications when high stick-slip is detected

PDF: Published on Pason, February 4, 2020

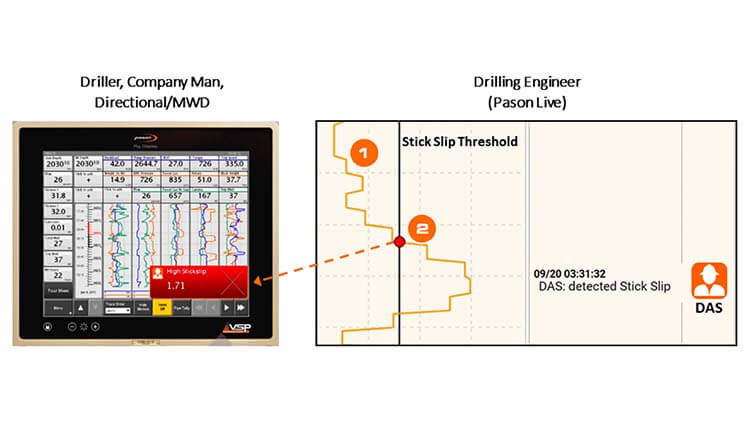

DAS Stick-Slip Detection

DAS uses a highly accurate model to estimate downhole stick-slip. ExxonMobil and Pason have validated this model against downhole tools from several different vendors. The system will automatically alert users when high stick-slip is encountered.